When the holidays rolled around, I started thinking about brewing again. I only brewed 5 batches of beer last year, which is at least half as much as I would have liked... In fact, if it had not been for an event that I wanted to brew beer for, and a free grain bill provided by a friend, I probably would not have even brewed at all - and that is even more depressing!

As my thoughts turned back to brewing, I dug into books about beer, thought more deeply about each beer I was drinking (that's a lot of deep thinking!), and got caught up on brewing podcasts. As I listened, a couple marked anniversary episodes - most notably

Experimental Brewing (1 year) and

Dr. Homebrew (3 years). In the latter, the hosts always ask the guests how long they've been brewing... Which got me to thinking.

Growing up in the Pacific Northwest, I was aware of craft (micro) brews early on. My first was a Redhook Ale (not ESB, but their original ale) in the mid-80s in high school. It was certainly interesting, but kind of a palate shock for a teenager whose primary experience had been drinking Rainier and Heidelberg! During my first 4 years in the Army, I still drank mostly American lagers, but was exposed to lots of other good beer by fellow Soldiers who had been stationed in or traveled to Europe.

With this, my palate began to shift, and I came home to the Puget Sound to a proliferation of craft beer and grunge. My preferences included the aforementioned Redhook Ale, Pike Pale & IPA, and many other more flavorful and often hoppy beers. I made friends with the local beer distributor (who latrer went on to become one of the founding three partners at Elysian) at the Olympia Top Foods while in college, and he taught me a lot about beer as he tipped me off to new labels and offerings 22 ounces at a time.

In about 1992, I drank my first homebrew, brewed by a lifelong friend. The details have long faded from memory, but I do remember a reddish, hoppy pale ale. It probably was not super, but he had made it himself. At home. It was not super dry - there was considerable crystal malt character, and the hop character leaned on the bittering addition; all of this was very characteristic of styles in the late 80s and early 90s, much different than the dry, late-hopped pales we have today. In the late 90s and early 00s, I actually watched a couple of friends brew while I drank beer and did very little other than ask questions and stir pots.

The fruits of one of those brew sessions, a Fuller's pale clone, was enjoyed streamside after work one day in the spring of 2004, right before the birth of my second son... It was a little undercarbonated (the swing-top probably needed a new gasket), but it was delicious: bready malt flavor almost hidden by fresh hop character. After several years of thinking about it, I decided to take the leap. I asked for a homebrewing kit for my birthday in August.

We never got around to buying the kit that summer. I guess I underestimated how much work juggling work, a two-year-old, and a newborn was going to be. In fact, we still had not gotten around to it on my following birthday. And then my unit got called up to go to Afghanistan.

While deployed, the closest I got to beer was Bitburger Drive, their NA beer. While younger troops dreamed about cars and girls, I was dreaming about food and beer. I found out that one of the senior NCOs I had working for me was an experienced homebrewer (in fact, he confessed that he had run out of time before we shipped out, and he had a carboy of brown ale sitting in his bathtub during our entire deployment!). I grilled him for info every chance I got. At one point, I accompanied his team on a 6-week op (in the Korengal Valley - but that is s different story)... We talked a lot about beer and brewing. We were embedded with a CAV troop, and saw a lot of action during that month and a half, but our beer discussions kept us sane.

During one of those discussions, he recommended Charlie Papazian's seminal book,

The Complete Joy of Homebrewing. He told me all I needed to get started was a kit and that book... I ordered it (along with

The Homebrewer's Companion) the minute I got back to Bagram. I think I read those two books 2-3 times each during my last 3 months in-country! I already had several recipes picked out and the books looked well-worn before I had ever even brewed my first batch!

We spent Christmas (and New Year's) in Afghanistan, but my wife really wanted to celebrate the holidays when I returned. I put the brewing kit at the top of my gift list! And this time I got it...

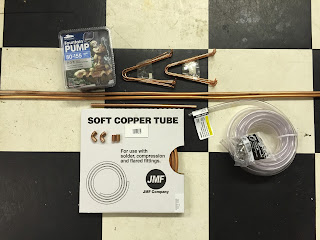

I was ecstatic when I unpacked my new homebrewing kit... A bucket with a lid, a carboy, a racking cane, some tubing, etc. along with an extract kit (Cooper's Original Series Bitter, which looks to have been replaced by "Real Ale") augmented with steeping grains, dry malt extract, and hops. I could not wait to get going! I think I brewed the very first weekend I was home...

I started like so many others, at that time at least, with a stove-top partial boil. I used a ceramic-coated steel canning pot. I steeped my grains until the water hit 165, then removed them and let them drain in a colander. I added my 3 lb. can of Cooper's liquid extract and 1 lb. of light dry extract and brought them to a boil. I followed the directions and added my hops when the homebrew shop owner's recipe said to do so. I put 2 gallons of filtered, cold water in the carboy and poured the hot wort through a colander and funnel into the bucket, then topped off with more filtered water. I added the Cooper's dry yeast sachet, and plopped the lid and airlock on the bucket.

I followed the instructions mechanically. I knew the basic process from reading

The Complete Joy of Homebrewing (3x - remember?), but I had minimal understanding... Similar to when you begin cooking for the first time, it's more about the algorithm of the recipe than the process and how the ingredients fit together to make the final product. Plus, like any other process-oriented task, it takes going through it a time or two before the timing and flow feel right. Despite what Charlie Papazian says, I found it hard to "relax" avoid worrying, and I had no homebrew yet! (I don't even remember if I drank beer while brewing this one.)

I did take good brewing notes (the can of Cooper's extract came with a short data sheet in the instruction packet). After two days, I measured the gravity; two days later, it was stable, so I "racked to secondary for conditioning." Like most people 10 years ago, I conditioned my beer in secondary - in my case a glass carboy. After two weeks, I ended up with 5 gallons of (under-attenuated) bronze-colored ale, which I bottle conditioned in a combination of new 22 oz. and recycled 12 oz. bottles. I was so close, and yer I still had two weeks to wait!

By the time the bottles from my first brew were carbonated and ready, I already had two more batches under my belt. I chilled a few bottles in the refrigerator, but one bomber went into the freezer for the quick chill... When it came out of the freezer, the cap came off with a satisfying "pop-hiss." It poured beautiful and clear, almost amber, with a beautiful head and wonderful hop aroma. Casting back, it also smelled characteristically like a liquid extract beer... This was not, I have since learned, necessarily

because it was an extract batch, but more a product of it being

a partial boil extract batch.

My first beer, albeit less-than-perfect (under-attenuated, extract-y, etc.), was a success! My mother-in-law, who is not really a beer drinker, even liked it. I was excited at my success, and even more excited that I already had two more batches nearing completion. I became obsessed with homebrewing, reading all that I could find, messing around with recipe calculators and watching the effects of different ingredients and amounts on virtual beers, and brewing at least once each month. I gained a reputation with my friends... The guy that finally got me started homebrewing became a regular brewing partner (one year, we brewed over 300 gallons together), and he started coming to me for brewing advice!

Ten years have gone by quickly. My boys, who were first inhibitors to brewing, progressed on as helpers; they loved hanging around on brew day and helping me bottle (which was great, because I loathed bottling). Now they're old enough that they have a fairly thorough understanding of the science of brewing, and they like hanging out occasionally on brew day less out of admiration and youthful desire to be part of what Daddy is doing and more just to hang out for the company. It won't be long before we can brew together while sharing a couple of homebrews. I'm not brewing as much as I have at times in the past, but I'm no less passionate about homebrewing.

Cheers!